You can share

- Share to Facebook

- Share to Google+

- Subscribe to our

- Share to Linkedin

- Share to Twitter

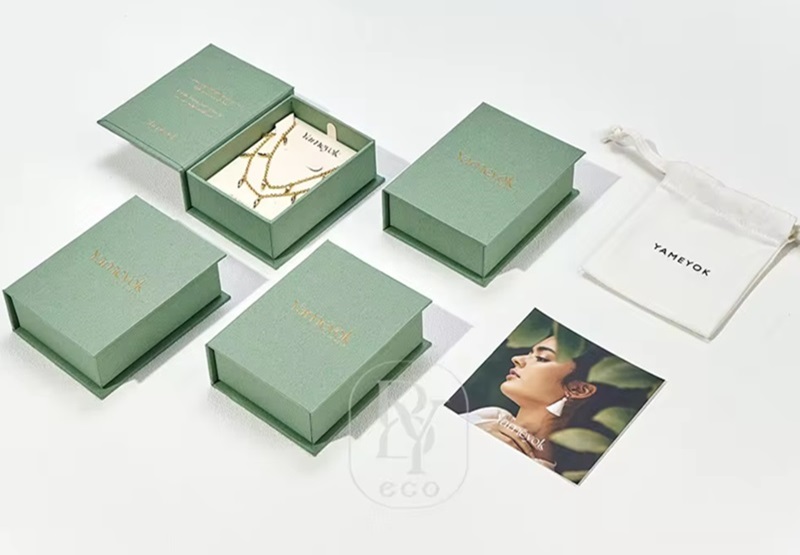

Every jewelry brand needs exquisite packaging to protect precious jewelry, or to enhance the brand image through packaging. However, the high cost of custom jewelry packaging often becomes a major challenge for jewelry brands in controlling overall expenses. How to reduce the cost of custom jewelry packaging while ensuring packaging quality and brand image?

The cost of custom jewelry packaging is closely related to the order volume. Usually, manufacturers offer lower unit prices for large-volume orders. Therefore, jewelry brands can reduce the price of each unit packaging box by reaching a bulk procurement agreement with packaging suppliers. Bulk procurement can not only save material and production costs but also obtain more favorable conditions in long-term cooperation.

During the procurement process, jewelry brands should predict the demand for packaging based on their own sales expectations. Avoid excessive procurement to cause inventory backlogs, and also ensure that the design and quality of the packaging box can maintain a certain uniformity and high standards. By reasonably predicting and planning orders, the production cost of each packaging box can be greatly reduced.

Packaging design directly affects production processes and material consumption. Jewelry brands can reduce costs by simplifying packaging design. For example, avoid too many complicated decorations, overly luxurious accessories, and cumbersome structural designs, and instead adopt simple and recognizable packaging solutions. Simplifying the design can not only reduce production difficulty and material waste but also reduce the overall weight of the packaging and reduce logistics costs.

In addition, the size of the jewelry packaging box is also an important factor. An oversized packaging box not only increases the amount of material used but also takes up more transportation space, resulting in higher transportation costs. Optimizing the size of the packaging box can not only save materials but also effectively reduce logistics costs.

The material of the packaging box is one of the key factors in cost control. High-end custom packaging boxes are commonly made of materials including leather, wood, cardboard, etc. Although these materials can enhance the luxury of the packaging, they are expensive. Jewelry brands can choose suitable alternative materials according to the needs of the target market. For example, using environmentally friendly cardboard instead of wood or using high-quality recycled materials can not only reduce costs but also help enhance the brand's environmental image.

When choosing the right material, you also need to consider the durability and safety of the material. Jewelry packaging boxes need to maintain their shape and protective functions during transportation and storage. Therefore, the choice of materials needs to take into account both cost and function to ensure the safety of jewelry in the packaging box.

The production processes of customized jewelry packaging boxes include printing, embossing, hot stamping, etc., and each process has different costs. Jewelry brands can choose the appropriate process to reduce the production cost of packaging boxes according to actual needs. For example, simple single-color printing is more economical than multi-color printing, and complex processes such as hot stamping or embossing will also significantly increase the cost of a single packaging box.

For some start-up brands or brands that focus on cost-effectiveness, some high-cost processes can be considered on limited editions or high-end series, while the standard models maintain simple and practical design and craftsmanship. Through this differentiated packaging strategy, cost control can be guaranteed while maintaining competitiveness in the high-end market.

Establishing long-term and stable partnerships with reliable packaging suppliers can bring more cost advantages to jewelry brands. Through in-depth cooperation with suppliers, brands can obtain more competitive quotations and enjoy more flexibility and quality services in the design and production process of customized jewelry packaging boxes. In addition, long-term cooperation may also bring higher supply chain efficiency, reduce production and delivery time, and further reduce costs.

When choosing the right supplier, jewelry brands should pay attention to the supplier's production capacity, delivery timeliness, and quality control system to ensure that the quality of the packaging box will not be affected while reducing costs.

Today, environmental protection has become a focus of many consumers, and jewelry brands should also follow this trend and adopt sustainable packaging solutions. Using recyclable materials, environmentally friendly inks and water-based paints can not only help reduce costs, but also enhance the brand's sense of social responsibility. This environmentally friendly packaging solution is also becoming more and more popular in the mad can win more consumer support for the brand.

For example, some jewelry brands have effectively controlled packaging costs by adopting lightweight designs and simple packaging forms to reduce unnecessary packaging layers and material waste. In addition, packaging boxes made of environmentally friendly materials can also reduce price fluctuations in raw material procurement in the long run.

Although customized jewelry packaging boxes are an important brand investment, jewelry brands can completely reduce costs while ensuring packaging quality through reasonable procurement strategies, design optimization, material selection, and long-term cooperation with suppliers. As market competition intensifies, reducing packaging costs does not mean reducing brand value, but rather creating more business opportunities through more efficient and environmentally friendly methods.